- E-mail: sales8@micmachinery.com

- Mobile: 0086-13083991987

- Whatsapp: 0086-13083991987

- Wechat: 0086-13083991987

- Shipment: exporting country

- Customer reviews: click on

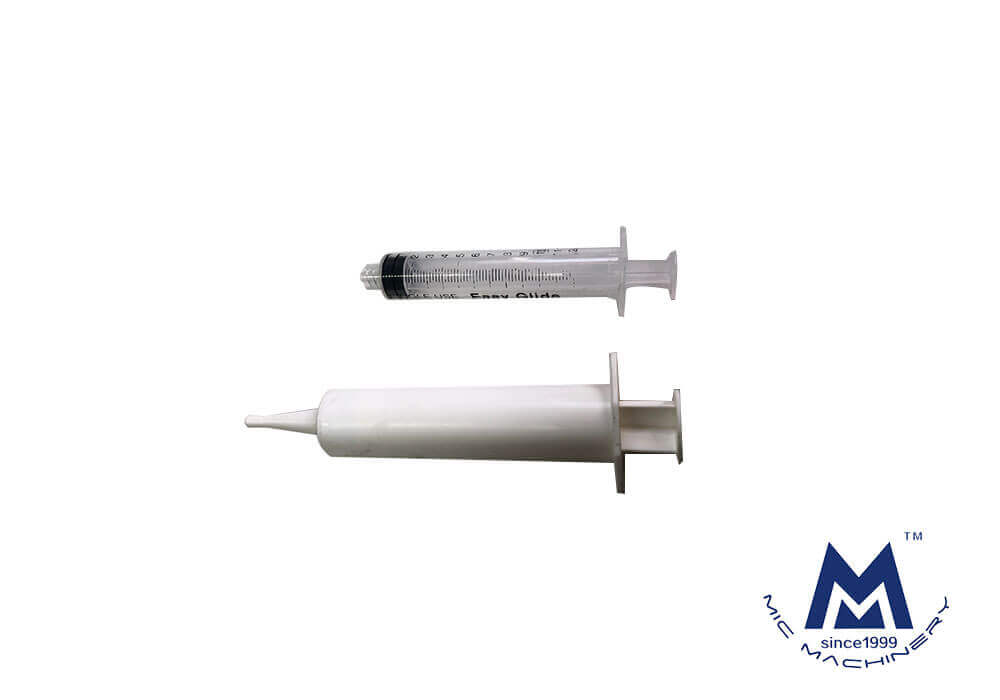

This machine suits for the plastic syringe and can fill many kinds of liquid,gel or paste.

Working progress:

Adopt cap sorter to sort the syringe(the pusher has been placed in the syringe and pushed to the bottom.).Then it will transfer the syringe to the main working station by rotary wheel.

About the filling station:

Filling by ceramic filling pump,Filling nozzle will sealed the tip of the syringe from the bottom to top by pressure filling,the piston movement will drive by the servo motor,filling volume and speed both can set and adjust on the touch screen.

About the Capping station:

The cap will transfer to the bottom of the syringe by vibrating disk, and then the cap is driven upward by the cylinder

Discharge:

The dial wheel rotates to the discharge station, and the syringe is pulled down from the dial by the discharge lever, and then the slide is slid down to collect (single slide down).

|

Voltage |

220V 50Hz |

|

Motor Power |

2KW |

|

Filling speed |

3000pieces/hour |

|

Filling accuracy |

+-1% |

|

Filling volume |

5-50ml |

|

Material tank |

20L(SUS 316) |

|

Air supply |

0.6Mpa |

|

Air consumption |

10 m³/h |

|

Filling nozzle |

1 |

|

Plugging nozzle |

1 |

|

Touch screen |

Proface(Japan) |

|

PLC |

Mitsubshi( Japan) |

|

Frequency converter |

Danfoss(Denmark) |

|

Servo motor |

Dorna |

|

High precision ball screw |

ABBA(Taiwan) |

|

Filling pump |

Ceramic filling pump(customized for gel) |

|

Switching power |

Mean Well(Taiwan) |

|

Pneumatic element |

SNS |

|

Photoelectric detection switch |

Autonics(Korea) |

|

Proximity switch |

Alif(Taiwan) |

|

Machine surface |

SUS 304 |

|

Filling nozzle |

SUS316 |

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Other Types Of Labeling Machines

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Empty Can Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Other Types Of Labeling Machines

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Empty Can Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Can filling machine